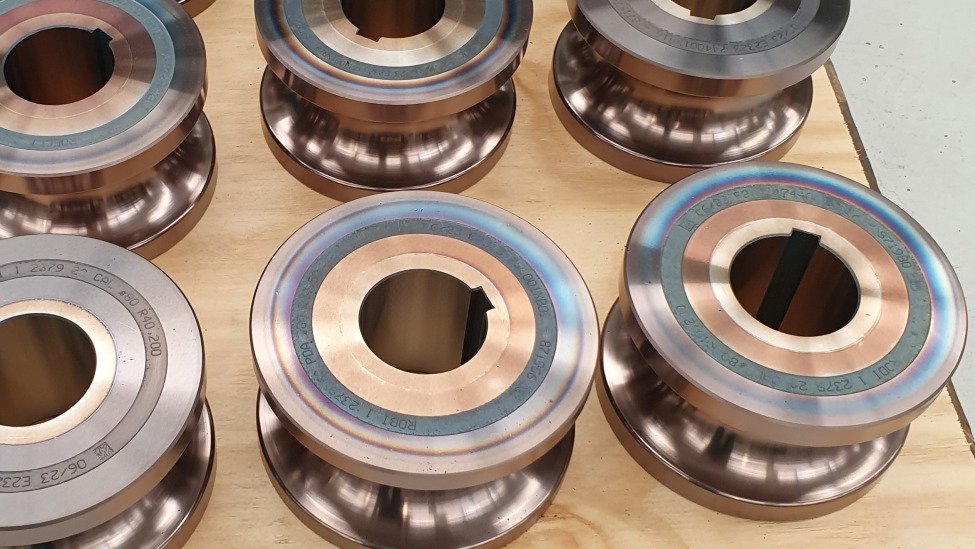

PVD COATINGS

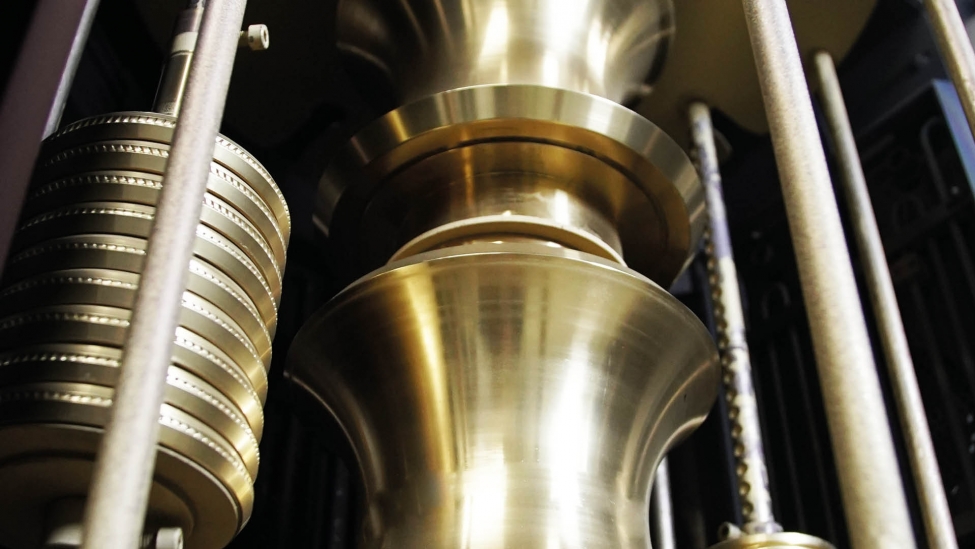

Our PVD technology coatings are the result of a partnership started years ago with the Laboratories of Legnaro | National Institute of Nuclear Physics. A INFN-branded new system was developed which allows the application of thin metal films on different types of substrates with the most innovative physical vapor deposition (PVD) technologies.

PROCESS: Ultra thin hard coatings, mainly nitrides, carbides and carbonitrades. The combination of the arc technology and magnetron sputtering allows to obtain high performing coatings.

MAIN APPLICATION: Anti-wear, anti-corrosion, anti-bonding and low friction solutions.

MAIN PRODUCTS: Rolls for the wire sector, rolls for metal sheets forming, cutting tools, inserts, molds, mechanical components and more.

Once the coating has worn off, the roll begins its service life with the base material.

PROCESS: Ultra thin hard coatings, mainly nitrides, carbides and carbonitrades. The combination of the arc technology and magnetron sputtering allows to obtain high performing coatings.

MAIN APPLICATION: Anti-wear, anti-corrosion, anti-bonding and low friction solutions.

MAIN PRODUCTS: Rolls for the wire sector, rolls for metal sheets forming, cutting tools, inserts, molds, mechanical components and more.

Once the coating has worn off, the roll begins its service life with the base material.

CAPACITY:

- Max Cylinder diameter: 600 mm

- Max Length: 700 mm

- Max Weight: 800 kg

- Applied on finished products (no need for grinding or polishing)

- Low cost

- The useful life of the roll is estimated to increase by about 40%

| Eurolls commercial designation | Material | Colour | Hardness | Thickness | Max working temperature | Roughness Ra | Coating technology | Substrate |

|---|---|---|---|---|---|---|---|---|

| EUKRIPTONIT | Combinations of Ti | various gold, grey, red | 1800-3000 Hv | 1-6 ym | 600 | 0,2 - 0,4 | PVD multi-layer multi-process | tool steel, high speed steel, cermet, tungsten carbide |

| EUKRIPTOKROM | Combinations of Cr | silver/grey | 1500-2500 Hv | 1-8 ym | 850 | 0,2 - 0,4 | PVD multi-layer multi-process | tool steel, high speed steel, cermet, tungsten carbide |

| EUKRIPTAL | Combinations of Ti, Cr, Al, Si | various grey, dark purple | >3500 Hv | 1-8 ym | 1100 | 0,2 - 0,4 | PVD multi-layer multi-process | tool steel, high speed steel, cermet, tungsten carbide |

Download Data Sheet

| PVD COATINGS | |

| EUROLLS COATING CATALOG |